LIP SEALS

Lip seals for pneumatic and hydraulic cylinders.

Produced by mould vulcanisation and finishing the lips by cutting.

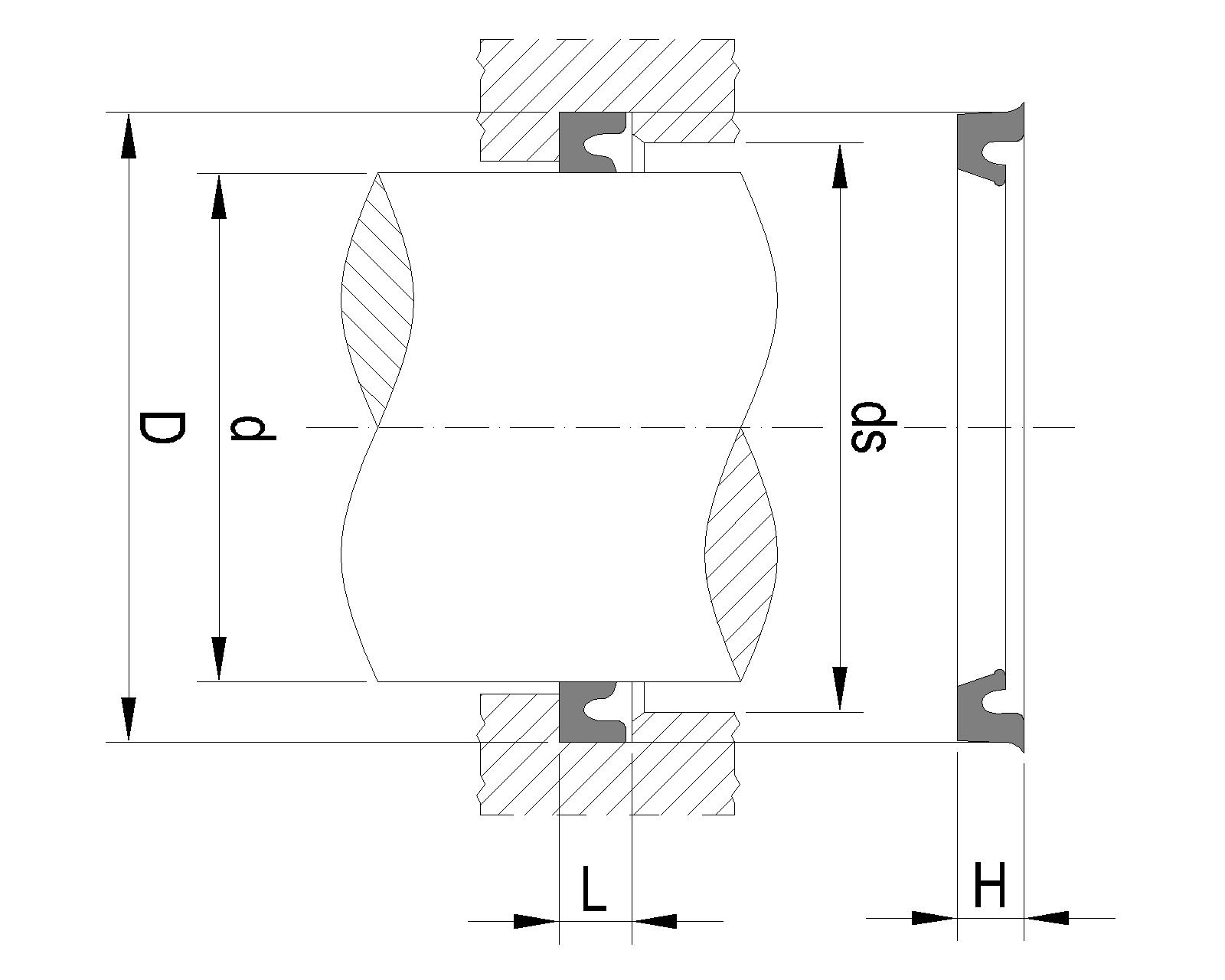

DIMENSIONS INDICATED REFER TO THE SEATS.

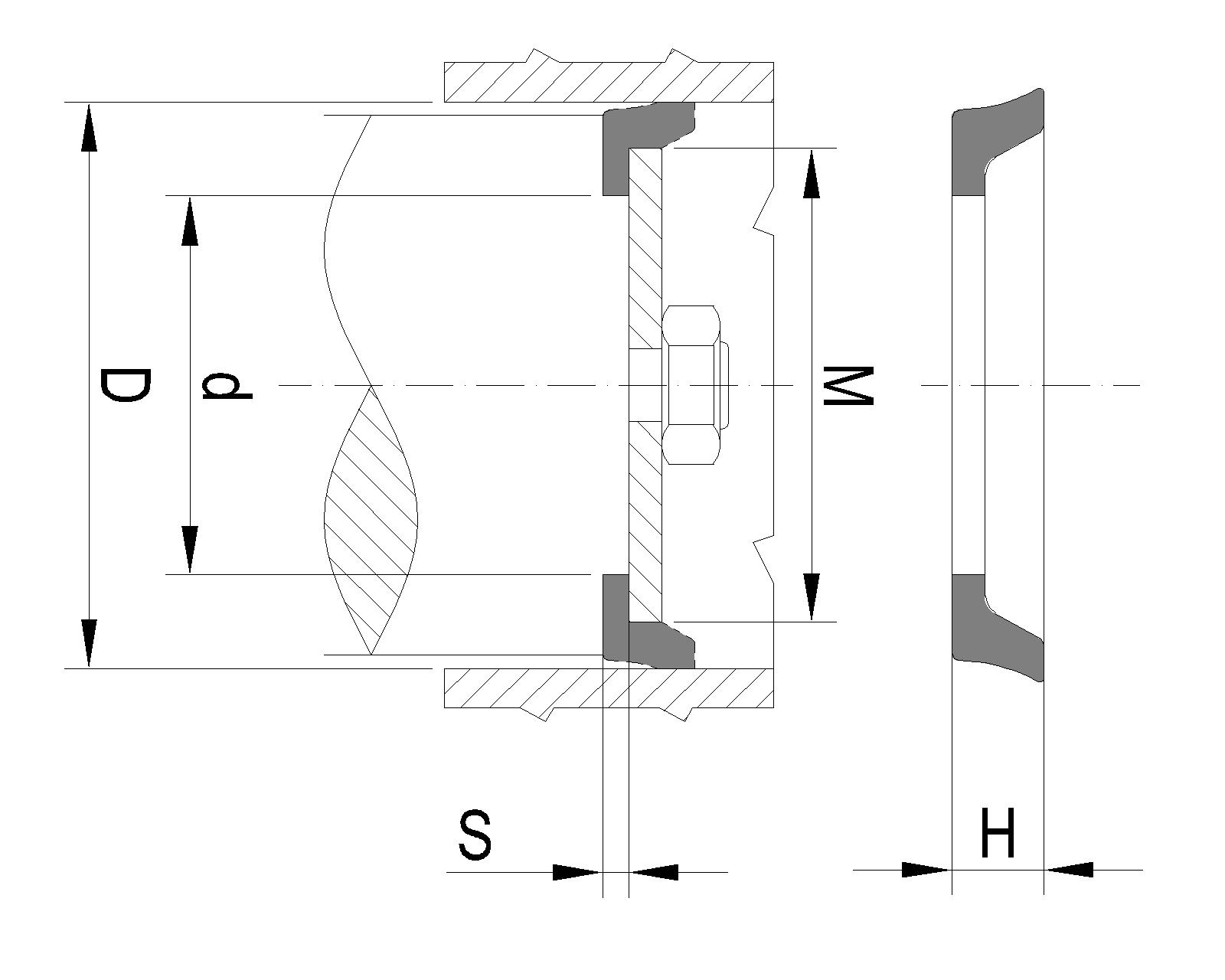

Gasket normally mounted on the piston with a plate as indicated in the technical drawing; the result is therefore a seal that is not completely automatic. They are commonly called caps and can be used with pressures that do not exceed 4 MPa (40 bar).

View the articles

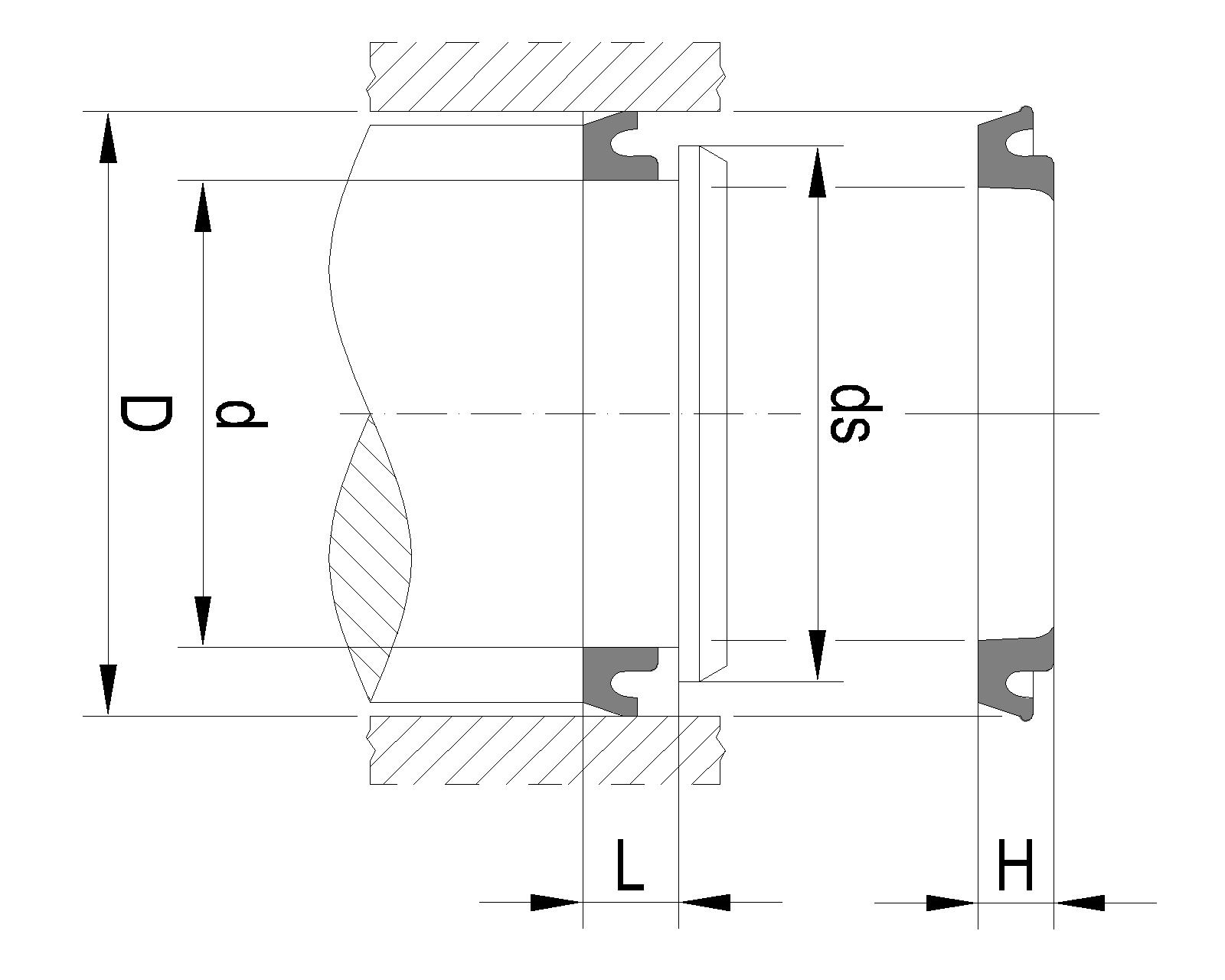

Gasket is suitable for dynamic seals on a single lip, the external one. It does not require a stop ring as the internal static seal lip, of a more robust shape, serves as a stop against the axial movement of the gasket in its seat. It supports operating pressures up to 8 MPa (80 bar).

View the articles

They are normally mounted on a cylinder with the function of an oil scraper or dust seal and must be compressed axially in their seat with a ring. The maximum operating pressure is 4 MPa (40 bar).

View the articles

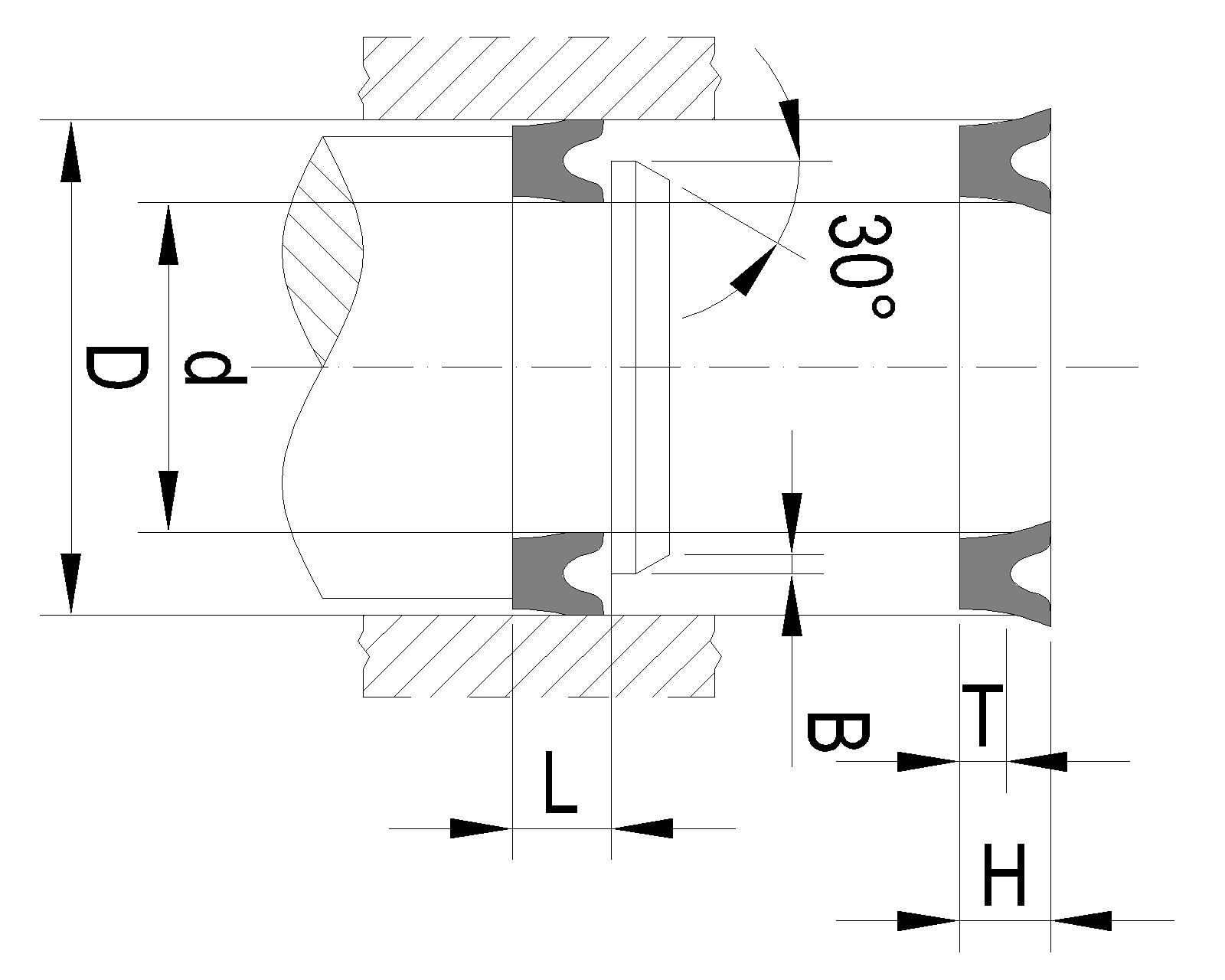

Structurally robust gasket and must be mounted with the interposition of a stop ring that prevents the gasket from moving axially in its seat.

The stop ring must not press the gasket into its seat, but must allow a gap of 0.5 ÷ 1 mm. Furthermore, it is necessary to drill a series of holes in the ring which have the purpose of equally dividing the pressurized fluid on the two sealing lips. These seals can be mounted on both piston and cylinder and can withstand pressures of up to 12 MPa (120 bar).

Gasket suitable for dynamic seals on a single lip, the internal one. It has an external lip that is higher and more robust than the internal one, thus providing a static seal, preventing the gasket from moving axially. It is therefore not necessary to use the metal stop ring. They are suitable for operating pressures up to 10 MPa (100 bar).

View the articles