ROD SEALS

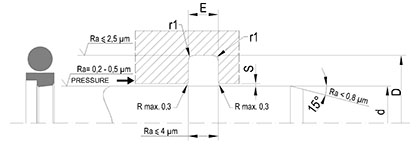

FPIGR (standard) Single acting rod seal. The gasket is bi-compound and consists of a PTFE compound pad coupled to an elastomer O-ring with an energizing function. Its main features are low friction, the absence of stick-slip and high wear resistance.

Available in different pairs of compounds depending on the conditions of use.

Types of use: Dynamic seal for reciprocating straight motion. Pressure: up to 80 Mpa (800 bar) Temperatures: - 60 + 200 °C depending on the O-ring material. Speed: = 15 m/s

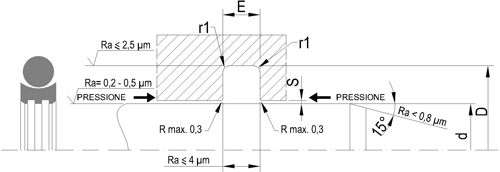

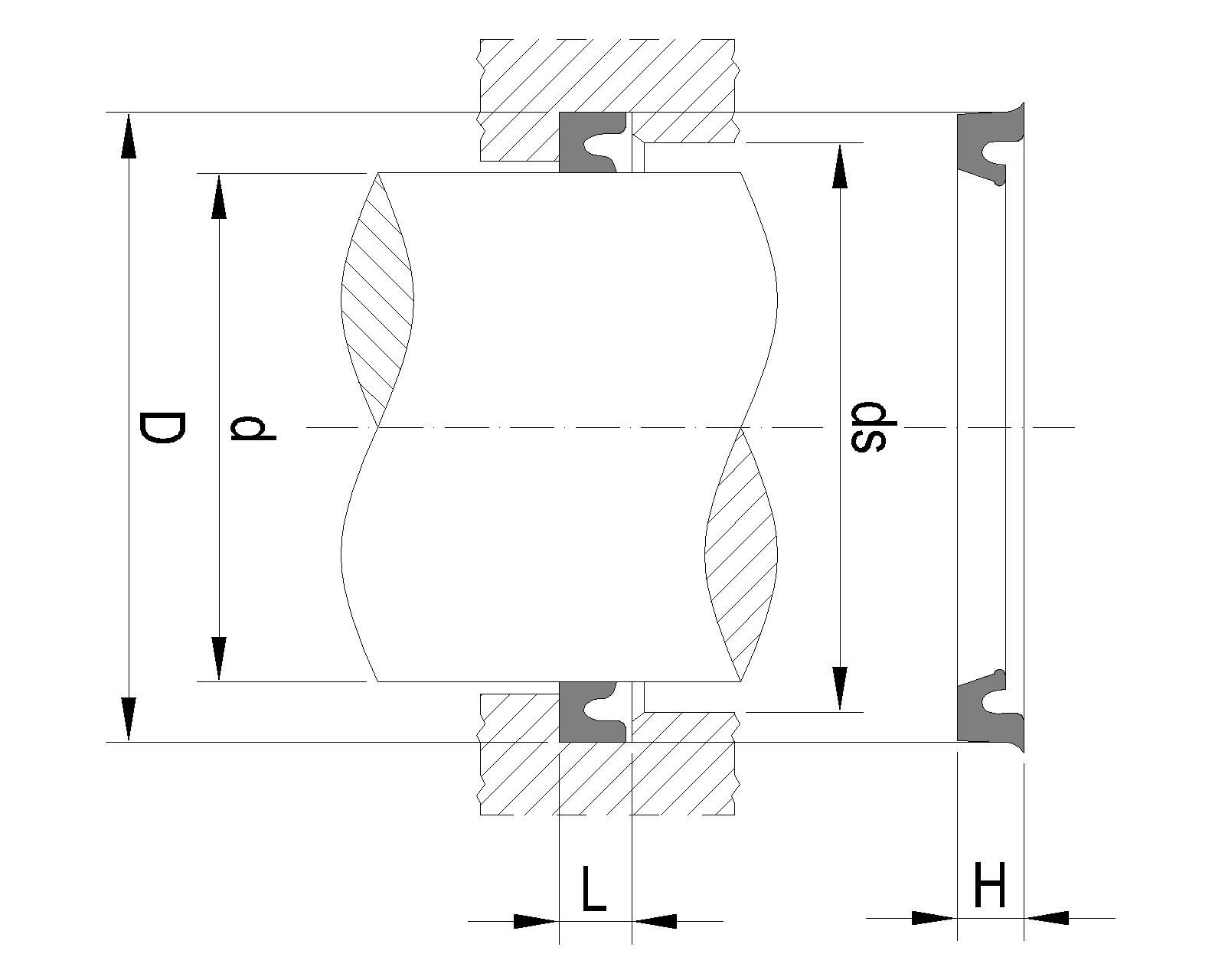

Bidirectional seal consisting of a PTFE compound pad coupled to an elastomer O-ring with an energizing function for rotating, oscillating or helical shafts. Mounted in slots in accordance with ISO 7425.

Diameters ø: 6 – 2500mm Pressure: up to 30 MPa (300 bar) Temperatures: - 45°C + 200 °C depending on the compound of the combined o-ring. Rotation speed: 1 m/s continuous in the presence of lubrication

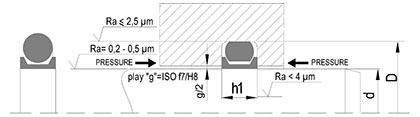

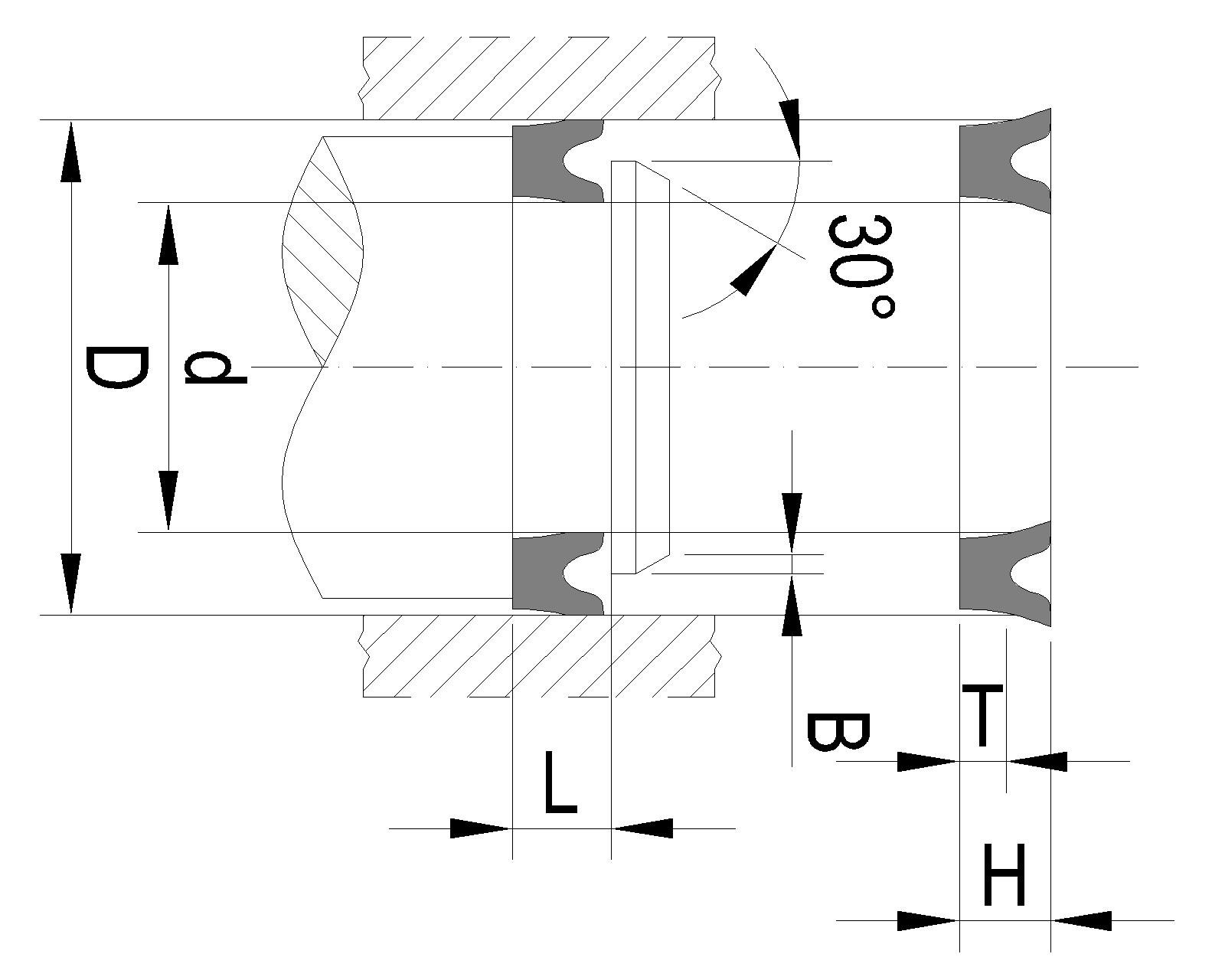

Double-acting seal for pneumatic and hydraulic use composed of two parts consisting of a shaped ring and an O-ring as a precompression element.

Operating temperature: from -30 to + 200 °C depending on the compound of the combined O-ring. Pressure: max. 20 MPa (200 bar) Flow speed: max. 4 m/s

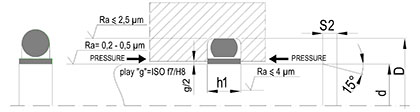

Double-acting seal for pneumatic and hydraulic use composed of two parts consisting of a shaped ring and an O-ring as a precompression element.

Operating temperature: from -30 to + 200 °C depending on the compound of the combined O-ring. Pressure: max. 25 MPa (250 bar) Flow speed: max. 4 m/s

Gasket suitable for dynamic seals on a single lip, the internal one. It has an external lip that is higher and more robust than the internal one, thus providing a static seal, preventing the gasket from moving axially. It is therefore not necessary to use the metal stop ring. They are suitable for operating pressures up to 10 MPa (100 bar).

View the articles

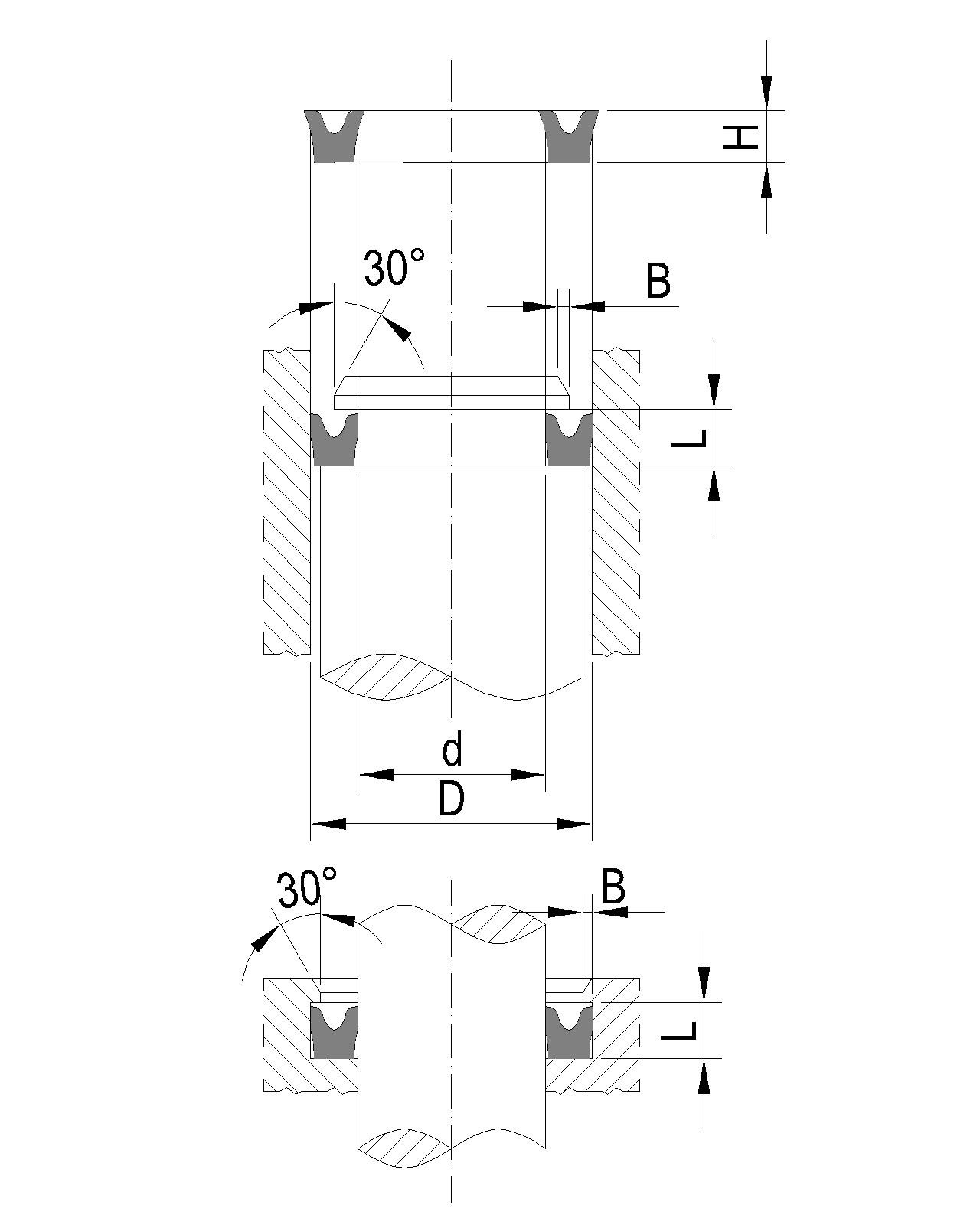

Structurally robust gasket and must be mounted with the interposition of a stop ring that prevents the gasket from moving axially in its seat.

The stop ring must not press the gasket into its seat, but must allow a gap of 0.5 ÷ 1 mm. Furthermore, it is necessary to drill a series of holes in the ring which have the purpose of equally dividing the pressurized fluid on the two sealing lips. These seals can be mounted on both piston and cylinder and can withstand pressures of up to 12 MPa (120 bar).

They are normally mounted on a cylinder with the function of an oil scraper or dust seal and must be compressed axially in their seat with a ring. The maximum operating pressure is 4 MPa (40 bar).

View the articles

Structurally robust gasket and must be mounted with the interposition of a stop ring that prevents the gasket from moving axially in its seat.

The stop ring must not press the gasket into its seat, but must allow a gap of 0.5 ÷ 1 mm. Furthermore, it is necessary to drill a series of holes in the ring which have the purpose of equally dividing the pressurized fluid on the two sealing lips. These seals can be mounted on both piston and cylinder and can withstand pressures of up to 10 MPa (100 bar).